|

|

| General Information | |

| About SCC | |

| Testimonials | |

| Race Staff | |

| Solar Racing History | |

| Resources | |

| Workshops | |

| Sponsors | |

| Giving to the SCC | |

| Internships | |

| 2025 Interns | |

| Media Page | |

| Join LinkedIn Alumni Group | |

| Event Information | |

| 2026 Route | |

| Event Updates | |

| Event Results | |

| Event Calendar | |

| Team Profiles | |

| Photos & Videos | |

| Weather Information | |

| Maps & Directions | |

| Team Support | |

| Webcasts | |

| Navigating Scrutineering | |

| Buy/Sell Parts | |

| White Papers | |

| Technical Documents | |

| Rules & Rules Updates | |

| Intent to Race Form | |

| Team Documents | |

|

|

|

Sponsored by: | |

|

Solar Car Challenge Event Update 2026-3

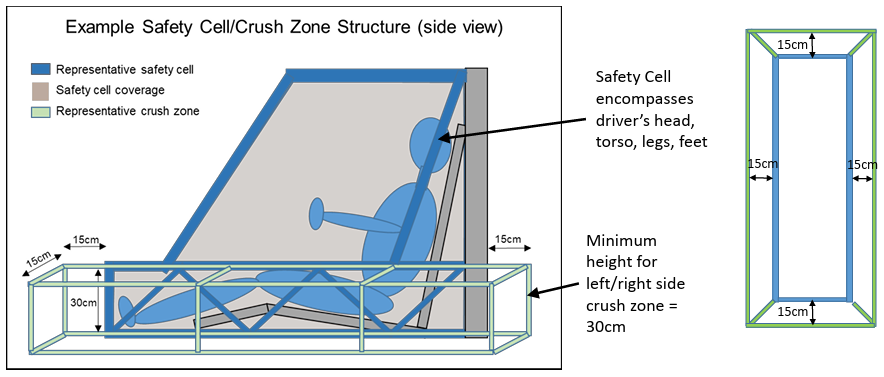

Crush ZoneRule 5.2.3 provides that a crush zone is defined as structural components outside of the safety cell that are designed to collapse in an effort to absorb some of the impact from a collision without impacting the driver space. The crush zone must provide driver and battery protection from front, side, and rear collisions Clarification: This rule implies that that there will be a structure composed of lighter-weight metal or composites attached to the frame designed to "crush" in the event of a collision. Foam products can be used to enhance this crush zone, but it must be a part of this lighter-weight structure. If foam is used to enhance the Crush Zone, that foam must be of a quality that will absorb impacts correctly. Inexpensive Styrofoam or other types of cheap foam are not acceptable. High density foam or honeycomb energy attenuating material is preferred. Shape of Crush Zone: The shape of the crush zone should be a rectangle providing protection up to 30 cm from the ground. This is designed to prevent intrusion into the driver’s compartment in the event of a side collision. The crush zone must be extended to protect a rear battery compartment.

Composite MaterialsRule 5.2.4 provides that the use of composite materials is permitted on the solar car. However, if composite materials are used in the safety cell, roll bar, or crush zone, the team must send a sample of the materials to a professional organization specializing in destructive testing to verify adequate structural strength and submit the resulting report to Event Officials for evaluation. Clarification: Scrutineering staff will want to see that you have properly evaluated the use of composite materials used in the safety cell, roll bar, or crush zone. This requires submitting your materials to a professional organization to determine that you have adequate structural strength. [Sample Analysis attached] Adequate structural analysis should include these tests:

Please see the Appendix that provides details, costs, and testing facilities. Adequate structural testing, should show that a side collision can handle a 3G force. This 3G force is three times the weight of the solar car including the driver. This 3G guideline is suggested for 2026. It will be required in 2027. The report from the professional testing organization must be submitted with your other registration materials on March 1st unless other wise extended by the Race Director. Here is a great website that discusses composite materials stress testing: https://www.addcomposites.com/post/mechanical-testing-of-composites PROPOSED CHANGES FOR 2027Many teams will be planning new vehicles in preparation for upcoming solar car racing events. We are making a formal announcement that several new Rules will be included in the 2027 Rules Document. They will not be required in 2026, but are intended to help guide your construction in preparation for 2027. If you are building a new car in 2026, you should consider following these new guidelines. There will be no “grandfathering” of vehicles in 2027. Anti-Intrusion to the crush zone area. Rule 5.2.3.3 - The area covered by the crush zone must have a solid anti- intrusion plate to prevent material from entering the driver compartment in the event of an accident. Crush zone material must be bonded to the anti-ingress plate. Rule 5.2.3.4 - Acceptable materials for crush zones are high density foam or honeycomb energy attenuating material. APPENDIX FOR COMPOSITE DESTRUCTIVE ANALYSISThese tests are widely used in the aerospace and automotive industries to validate material performance. A summary of the verified standards and their specific applications is provided below: 1. Tensile Testing (Strength & Stiffness)

2. Compression Testing (Crushing & Buckling)

3. Shear Testing (Interlaminar & In-Plane)

4. Flexural Testing (Bending)

5. Impact & Fracture Testing

Testing Requirements

Average Cost of Destructive Composite Testing (2026 Estimates)

Below is a list of testing facilities located in proximity to key team clusters as of 2026. 1. Texas (The Primary Hub)

2. California (Los Angeles & Orange County)

Appendix Information provided by Lucas Kiowski, Iron Lions Solar Car Team, Greenville, Texas. Attachments:

|

||||||||||||||||||||||||||||||||||||||